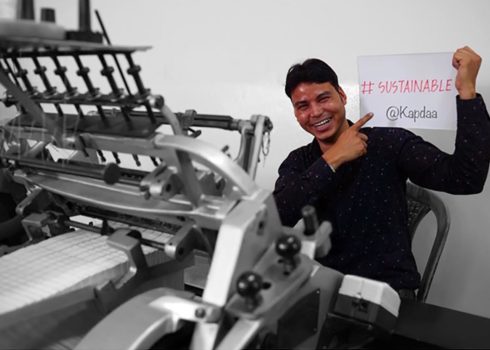

Designer Spotlight: KAPDAA

1.) Tell us about your brand, the over-arching idea of the brand and what makes KAPDAA unusual in the sustainability movement?

At KAPDAA ‘every piece matters to us’, we work with fashion/interior designers, textile weavers, mills etc. to make sure their beautiful fabrics don’t go to waste. By turning their excess materials /offcuts/end of rolls into unique and sustainable branded products, such as notebooks, pens, eye masks, luggage tags, purses etc. We give a new lease of life to production offcuts for our clients so that they can become part of a new accessories range or giveaway items at trade shows and events.

With 15% of textiles within the fashion industry ending up on the cutting room floor, we knew that we had a global responsibility to develop a revolutionary circular business model for creating day-to-day products. Through this, we have developed a new zero-waste concept with a streamlined form of waste transformation, where we can find a new purpose for all kinds of post-production materials.

2.) As a member of the textile industry, we admire your commitment to sustainability! Please tell us what inspired you to start this business?

My inspiration for Kapdaa – The Offcut Company started when I saw so many beautiful fabric offcuts going to waste in my mother’s fashion studio in Mumbai. I had always been passionate about solving problems in a unique way after studying Applied Art, Marketing & Advertising and Creative Economy & Management at university. So, I had my big light-bulb moment when I realized that I could make something completely new and exciting from these materials, which would have otherwise gone to waste.

We first started out making bookmarks from our own leftover materials and thought this simple solution was such a great idea, that we wanted to share it with the rest of the world! So, we then moved onto creating handmade bespoke notebooks for fashion, mills and interior designers. This was the perfect way to use my design skills to help brands creatively communicate with their audience, whilst also establishing new sustainable initiatives within the industry. This was the big start for us, but we didn’t stop there… we knew that there were still so much we could still do with these offcuts and since then we’ve spent time developing more and more products, from luggage tags, eye masks, wallets and pens!

3.) We believe in the Humanity of Hand Made. Your primary products are hand bound notebooks. What does the production lead time look like from customer commitment to finished notebooks?

One of our key social aims at Kapdaa is to preserve and grow the handcraft skills of individuals who are losing their livelihoods due to the digital world, which is why we chose to create hand-bound notebooks which require hand bookbinding and screen printing skills. In terms of lead time, it would take approximately 6 weeks from the time we receive our client’s offcuts to receiving the finished notebooks. From cutting the papers, to hand-stitched binding, printing, pasting and packing the notebooks it is all done by hand. You can watch a video of how we make our offcuts notebooks here: https://youtu.be/U2l7iDKKrjU

4.) If an individual or company doesn’t have offcuts or wastage to use for notebooks, yet they love your idea, how can they still get involved?

We can help them source offcuts from our current clients to create their books, depending on what kind of fabrics they are looking for. Or we can salvage materials from textile companies who are either closing down / moving premises and have fabrics they want to get rid of; we’ve gone through skips to save beautiful offcuts before and used them for various ideas! Or they can give us some of their old/unused clothes which we can convert into books for them too.

5.) What long-term opportunities and goals do you see for your team’s creative viewpoint and products? In 15 years what will KAPDAA look like?

I would like to tackle the waste issues from both sides, starting off with KAPDAA becoming the one-stop place for reusing all kinds of offcuts in a sustainable way! It would be amazing to see our zero-waste concept reaching throughout all industries for marketing purposes. With either fabrics, wallpaper, rubber or metal, there is no limit to where our streamlined waste transformation can be applied to within all sectors of the market!

Once brands and consumers are both accustomed to turning offcuts into day-to-day branded products, then we can develop a business-to-consumer platform, where end users could send in their own fabrics or clothes to remanufacture into something new. This way we’ll be able to involve the consumer within the entire production process, ensuring that they can actively partake in this sustainable cycle. Hopefully, our versatile zero waste initiative will be able to inspire more brands and consumers to see their waste materials in a new light by giving them a new purpose.

To conclude in 15 years’ time, I would like Kapdaa to be a brand creating day-to-day products sustainably and beautifully that become a household name.

6.) What is the most rewarding part of creating and operating a sustainable company?

It is always a pleasure hearing the comments and appreciation we receive from our clients and followers as we continue to work towards our zero waste goals within the fabric industry. It’s so encouraging seeing how we can inspire businesses to think differently about their leftover materials when ‘every piece matters’.

As the practices of sustainability are always expanding, this offers us the opportunity to learn and implement new actions every day in our business. We feel privileged that we can share our learnings with our clients and followers.

Also, throughout our sustainable journey, we have been creating new jobs for skilled labor in India, especially for screen printers and bookbinders that have been losing their jobs as machines replace their trade. Through our work together, we will ensure that the handmade art stays alive! As this is something that is very important to us, we will continue liaising with local companies to build supply chains that involve individuals from the local community – from our ethically sourced factories to our friendly delivery man – so that small ethical businesses are involved within our whole process.

Pat Nugent

Pat Nugent